Our story

Learn how Distro started and why we're helping designers with production.

The beginning

I'm Jarek Ostrowski, Founder of Distro. This is me, trying to look cool by taking a picture of myself in my garage, admiring what would eventually become the desk I sit at today. It was 2022, and I had just left my high-paying Product Design job at a prominent tech company to start a business—one in a completely different sector from where I'd spent my entire career.

I've always had a passion for woodworking. I love everything about it—the process, the smells, the woods, the outcome, everything. Whenever I had downtime and access to equipment, I would try to make my own furniture.

When I finally embarked on this venture, it was a bit scary, I'm not going to lie. My wife was five months pregnant, and while we had some savings, not having an income was unfamiliar territory. That's when I got to work, creating something around my passions: woodworking, branding, and working from home. Out of that came Lone Birch.

Lone Birch

The first thing I did with Lone Birch was launch an Etsy store. Etsy was the perfect platform for what I was trying to do at the beginning. I would come up with a new design, make a prototype, take some photos, and add it to my store. I did this consistently throughout the week. Then I'd run ads on them for a few weeks, see which ones sold, and remove the ones that didn't. I actually still use this technique today, and it's all because of Made to Order (MTO).

One of the things I learned early on was that being MTO almost guarantees success—it's basically a superpower. It gives you the ability to experiment and launch designs at will until you find the ones your customers want to buy. It also doesn't require inventory, and you only spend money after you make it. And the best part? I found that my customers were more than willing to wait. With a solid 5-7 day turnaround, most never even noticed the wait.

I repeated this process over and over until one day, I started seeing orders come in for a particular product that I had no expectations for—the lap desk.

The Lap Desk

In the early stages, when I was coming up with new products, I kept seeing these lap desks that seemed to be selling, but I didn't see one that I would personally buy. They either had a cheap plywood top, an ugly fabric, or bad photos. So I decided to try it out because... why not?

I went to the drawing board and designed a lap desk that I would personally buy—one that was best in class. I used Walnut for the top, added a small lip so laptops or pens wouldn't slide off, tested fabrics for the softest and nicest design, tested different fills, and materials for the handle until I came up with what I thought was the nicest lap desk on the market—one I would buy.

Once I launched it and started running ads, sales started coming in immediately. From then on, most of my time was spent in the shop making lap desks instead of designing and launching new products. When the holidays came around, I had a massive backlog of orders and found myself overwhelmed, realizing I needed help, but I never imagined how much it would cost me.

No win situation

There are two ways to grow your physical products business—outsource or hire/expand. When I looked for companies to outsource to, local shops were few and far between, and the ramp-up time would take months. Not to mention I'd be on the hook for inventory, and I didn't want to spend money on products I hadn't sold yet. I loved being made to order and wanted to stay that way, but no shop or contract manufacturer in their right mind would do that. Those kinds of companies rely on inventory runs to stay in business and keep the lights on.

The next best option was to look at garage space where employees could come and make products out of the shop. That meant I would also have to double or triple my equipment, which came with the territory if I went this route. After hearing the broker say the landlord wanted a minimum 5-year commitment, I was out. There was no way I was going to commit to that. As successful as Lone Birch was getting, it wasn't financially responsible for me to promise $150,000 to someone for a business I'd just started, especially with a baby on the way.

On top of all this, I still had issues with shipping costs. These lap desks, the largest at 34", cost an arm and a leg to ship out west. Based here in New Hampshire, shipping one to Washington or California was upwards of $70, meaning I either broke even or lost money on those orders. That's when I knew I had to get creative.

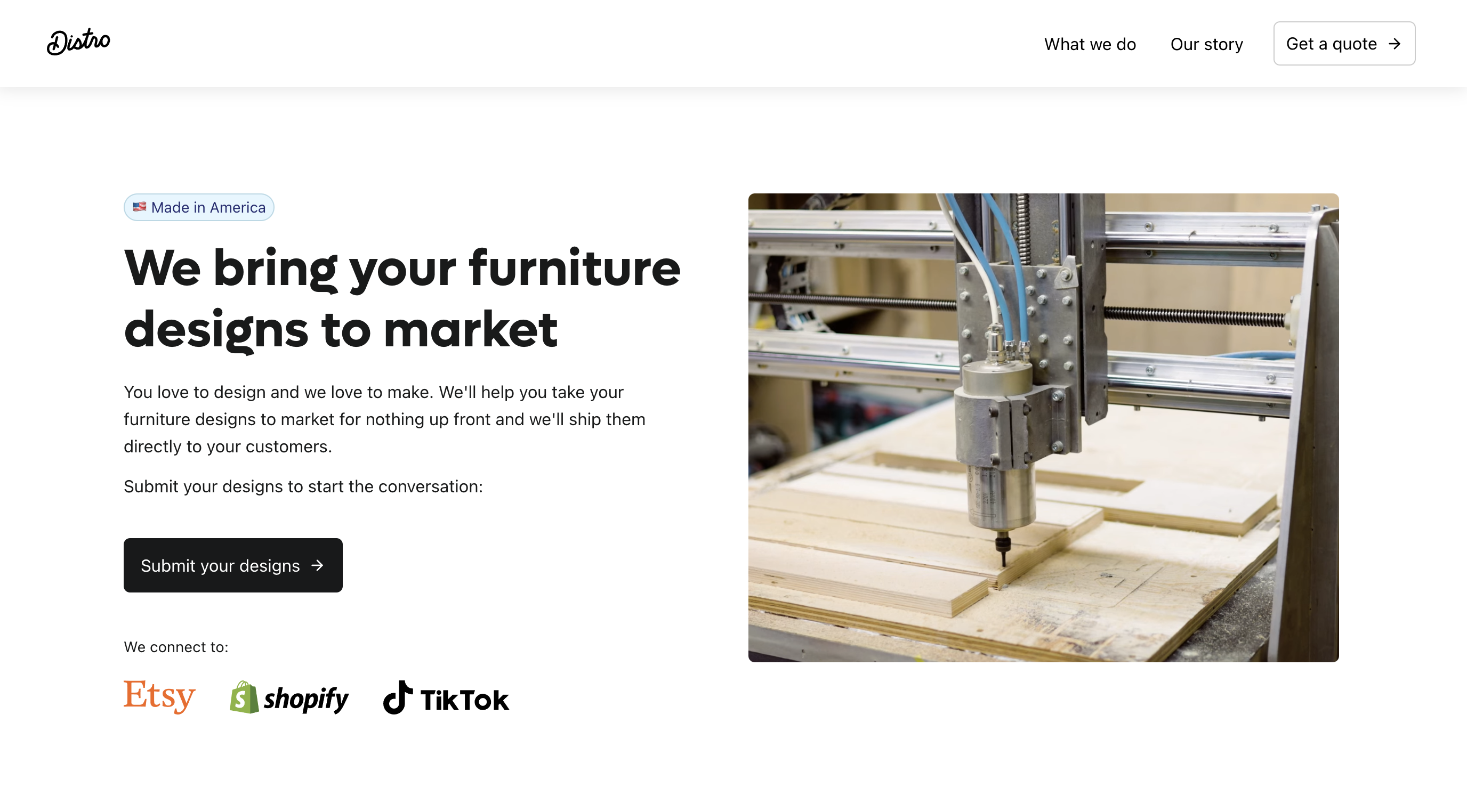

Distro is born

Outsourcing or leasing a space wasn't an option—and neither solved my shipping cost issues. After talking to people and giving it a lot of thought, I realized something: there are thousands of highly skilled woodworkers across the US, more skilled than me, with their own equipment, who could easily make my products. If I could tap into that network and trust them to meet my quality standards, work on time, and operate on a made-to-order basis, it would be perfect.

So I thought, why not give it a shot? It was better than the alternatives. I reached out to a former colleague to help build software to streamline the process. Orders could come in, get assigned to vetted makers near the customer (saving on shipping), and the makers could print labels and schedule pickups themselves. It was completely hands-off for me. Within a few months, while I continued recruiting makers, the software was ready, and we onboarded our first makers.

A few weeks after launching, it hit me: "I'm at my desk, not in my shop, while others across the US are making, packing, and shipping my products." I had cracked the code for scaling a business—staying made-to-order, avoiding overhead, launching new products anytime, and saving 60% on shipping for west coast orders. That's when I knew I had to turn this into a business to help others.

Now, designers can do the same. We'll make a sample (free), connect to your store, and handle everything—making, packing, and shipping your products, on demand.

Jarek Ostrowski

Founder, Distro

jarek@distromfg.com

Ready to get started?

Request a quote so we can start making your products on demand.

Request a quote

Have questions? Contact us →