What is Distributed Manufacturing?

Explore the benefits of distributed manufacturing and how it decentralizes and transforms traditional production models to enhance efficiency and adaptability.

Localized Production

Distributed manufacturing involves setting up production facilities closer to the end users. This method significantly shortens the supply chain and reduces the dependence on central factories, thereby speeding up delivery and reducing transport costs. This approach not only makes manufacturing processes more responsive to local market demands but also enhances the ability to customize products regionally.

Supply Chain Resilience

In distributed manufacturing, the diversification of production sites contributes to a more robust supply chain. By not relying on a single source or location, manufacturers can avoid disruptions, adapt to external pressures such as tariffs or political instability, and maintain continuous production under various conditions. This resilience is vital in today’s dynamic market landscape.

Collaboration with Partners

Integrating third-party manufacturers into the production strategy is a hallmark of distributed manufacturing. This collaboration enables companies to scale up or down quickly based on demand without the overhead of maintaining large facilities. It also opens opportunities for innovation by combining diverse skills and technologies from different partners.

Benefits of Distributed Manufacturing

Cost Efficiency

Distributed manufacturing reduces overall production costs by minimizing the need for large, centralized warehouses and extensive distribution logistics. This system allows for significant savings on shipping and storage, making it possible to pass these savings on to the customers or reinvest them into further innovation and development.

Reduced Environmental Impact

By shortening the distance products travel from factory to consumer, distributed manufacturing substantially lowers carbon emissions associated with transport. Furthermore, local production often uses regional materials and resources, which supports local economies and reduces the environmental impact of importing raw materials.

Enhanced Production Flexibility

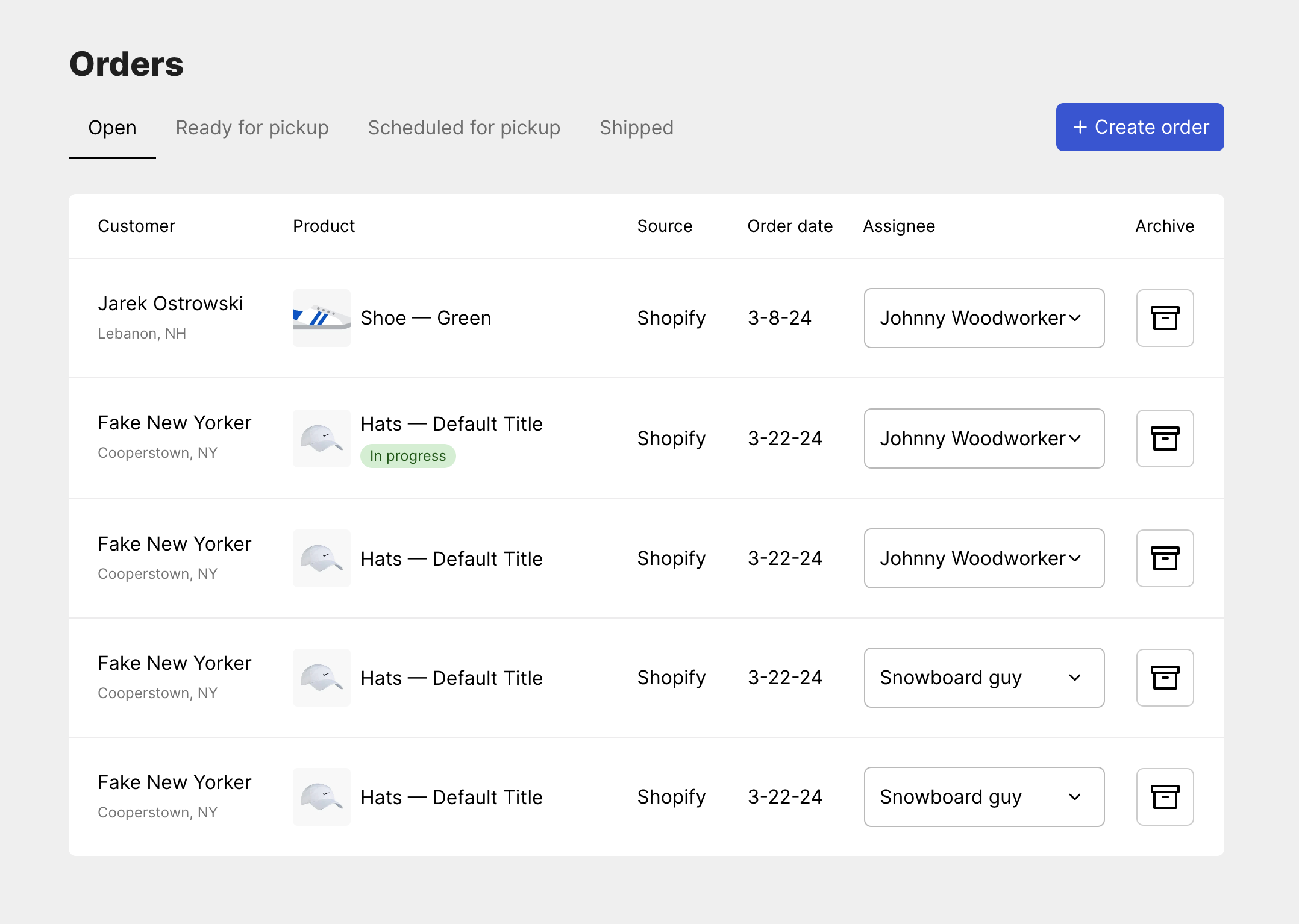

Our software is specifically designed to maximize the benefits of distributed manufacturing. It facilitates seamless communication between multiple manufacturing sites, integrates real-time analytics to monitor production and demand, and provides advanced tools for efficient order management. With our solution, businesses can truly harness the flexibility and efficiency of distributed manufacturing to stay competitive in a global market.

Explore our product

Ready to get started?

Request a quote so we can start making your products on demand.

Request a quote

Have questions? Contact us →